With the belief that good people make a good company

Molding Technology Center

HOME > Research Institute of Technology > Molding Technology Center

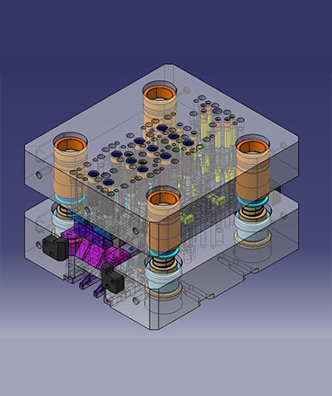

Molding Technology Center designs and makes

a variety of products ranging from ultra-precision

thin molds to large automobile molds.

Core Technologies

Core Technologies

Main Engineering Techniques

Main Engineering Techniques

Equipment Information

Equipment Information

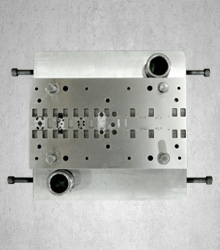

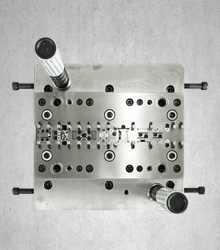

Precision Press MoldMobile, Laptop, Semiconductor(Lead Frame)

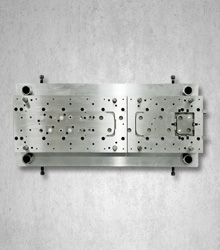

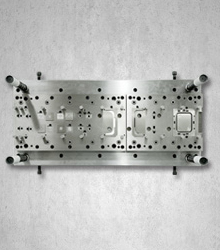

Large Press MoldElectronic Vehicle, ESS, Automobiles

Thin-Plate Precision Molding

This molding technology is applied to make ultra-precise, delicate, and small parts products with 0.10um of tolerance, such as Lead Frame, Semiconductor, and Shield Can parts.

Progressive Molding

This molding technology makes it possible to implement the press technique of transferring multiple processes sequentially for continuous work, and to maximize productivity through the improvement in innovative processing efficiency. Compared to the one-process based molding technique, the progressive molding technique can greatly increase an output in a stable way and improve quality at the same time.

Deep Drawing Molding

This molding technique is applied to mold a container with a certain seamless shape by imposing the front axis force on a plate with the use of the equal-shaped punch and die. It is used to make a drum, a cylinder with angles, or other complex shapes.

Wire Cutter Machine

Surface Grinder Machine

| Equipment | Model | Quantity | Remarks |

|---|---|---|---|

| Press | CS-200 | 2 | 200T, 5T |

| Wire Cutter M/C | AG400/600L | 4 | ¢0.1 ~ ¢0.3 |

| Super Drilling M/C | NSD600TG | 1 | ¢0.3 ~ ¢3.0 |

| Milling M/C | HMT-1100 | 1 | |

| Lathe M/C | NARA-4300 | 1 | |

| Band Saw M/C | HV-400N | 1 | |

| Surface Grinding M/C | YGS-116A | 1 | |

| Forming Surface Grinding M/C | DFG-250MB | 2 | |

| Bench Drill | 2 |

ENGLISH

ENGLISH KOREAN

KOREAN